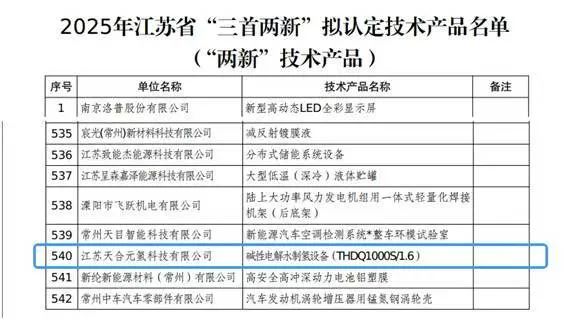

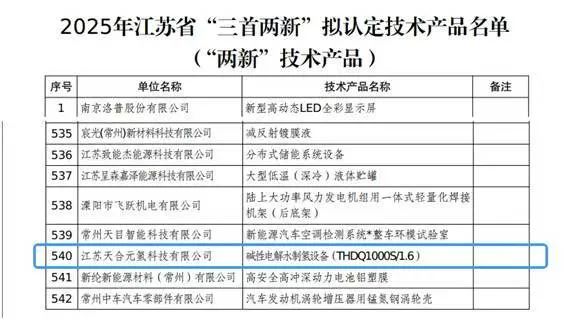

Recently, the Department of Industry and Information Technology of Jiangsu Province announced the list of "Three First and Two New" certified technology products in Jiangsu Province for 2025. The Tianqing series alkaline electrolysis water hydrogen production equipment (THDQ1000S/1.6) independently developed by Trina GreenHydrogen has been successfully selected for the "Two New" technology product list, marking that the equipment has obtained provincial authoritative recognition in terms of technological innovation and industrial application, and has become a benchmark achievement in the field of hydrogen energy equipment in Jiangsu Province.

The Tianqing series alkaline electrolysis water hydrogen production equipment selected this time is a 5MW high-power complete set of equipment independently developed by the company, with a single rated hydrogen production capacity of 1000Nm ³/h and a system pressure of 1.6MPa. It is suitable for various scenarios such as wind solar hydrogen production and industrial gas substitution. The device has achieved multiple technological breakthroughs through the collaborative innovation of catalyst, diaphragm, and electrode structure: the power consumption during full load operation is 10% lower than the industry average level; The upper limit of current density reaches 5200A/m ², which is 33% -73% higher than similar products and reduces the footprint by 28%; The power operating range has been expanded to 30% -120%, which can adapt to fluctuating renewable energy sources; The purity of hydrogen gas under all operating conditions exceeds 99.97%, and after purification, it can reach 99.999%, with a leakage rate of only 0.0128%/h, far exceeding the national standard requirement of 0.5%/h.

At the level of technological innovation, the three core breakthroughs of this equipment lead the industry's development: firstly, the development of hollow spherical porous high specific surface area catalysts, which are prepared by a one-step co precipitation hydrothermal method, significantly improving electrolysis efficiency; The second is to develop polyamide/carbon quantum dot modified hydrophilic membranes with a surface resistance as low as 0.16 Ω· cm ², effectively reducing energy consumption and expanding the operating range; The third is to adopt a plate mesh structure for electrode plates, optimize flow field distribution, and further reduce system energy consumption. These innovations have enabled it to pass the "Leader" certification of the China Hydrogen Energy Alliance, and its technical indicators have reached the domestic advanced level.

At present, the device has been successfully applied in multiple projects, achieving stable hydrogen production under fluctuating wind and solar power conditions. It has also been exported to overseas regions such as Spain, Portugal, South Korea, and Australia, and has been highly recognized by domestic and foreign users. As of 2025, the company has reached cooperation intentions with more than 10 domestic and foreign enterprises, further expanding its international sector.

From the perspective of social benefits, the promotion of this equipment will effectively promote the construction of a "new energy+green hydrogen+energy storage" system. Each device produces about 712 tons of hydrogen annually, can convert 28.28 million kilowatt hours of electricity, saves about 8.48 million tons of standard coal annually, and reduces CO ₂ emissions by about 22.62 million tons, providing solid support for achieving the "dual carbon" goal. At the same time, the comprehensive localization of its core components will drive the coordinated development of upstream and downstream industrial chains, and enhance the independent and controllable level of hydrogen energy equipment in China.

n the future, Trina Green Hydrogen will take this selection as an opportunity to continue promoting the iteration of alkaline electrolysis water hydrogen production technology, expanding its large-scale applications in energy, transportation, chemical industry and other fields, and helping the high-quality development of the hydrogen energy industry in Jiangsu Province and even the whole country, contributing the "Chinese solution" to the global energy transformation.